Description

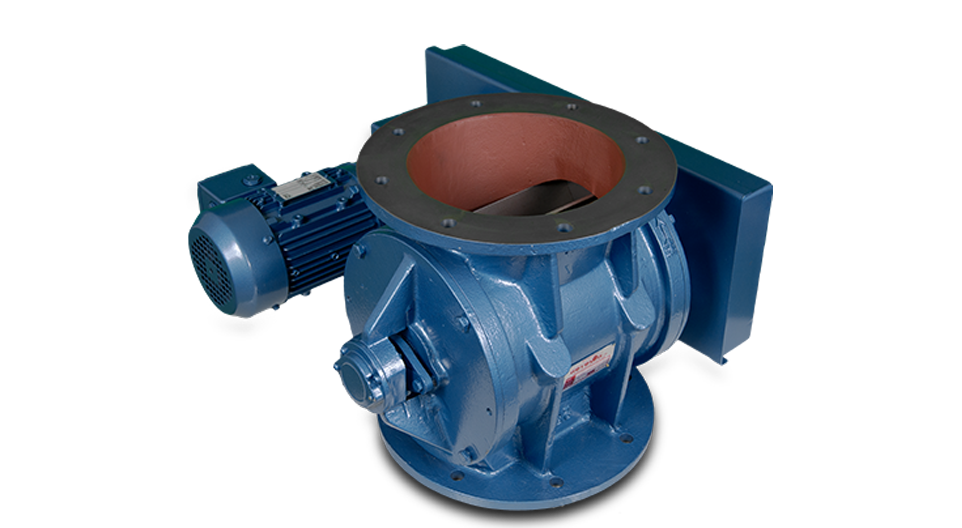

A Rotary Airlock Valve is an industrial valve commonly used to regulate the flow of bulk materials while preventing air or gas from escaping or entering a pressurized system. It is primarily used in pneumatic conveying systems, dust collection systems, and bulk material handling processes to control the flow of materials such as powders, granules, and pellets, while maintaining a sealed environment.

Key Components of a Rotary Airlock Valve:

Rotor (or Paddle):

The rotor is a set of blades or paddles mounted on a shaft inside the valve body. As the rotor turns, it discharges or receives material from the hopper or inlet while ensuring that the air or gas does not leak out of the system.

Valve Housing:

The housing encloses the rotor and is where material is introduced and discharged. It is typically made from high-quality metal such as cast iron, stainless steel, or other durable materials suited for the specific application.

Seals:

Seals are used to prevent air leakage around the rotor. These seals are critical for maintaining the integrity of the pneumatic system and for preventing contamination of materials. The seals are usually made of elastomers or other durable materials designed to withstand the conditions of the application.

Inlet and Outlet Ports:

The valve typically has two ports: one for the material to enter (inlet) and one for the material to exit (outlet). These ports can be positioned at various points depending on the design and application.

Drive Mechanism:

A motor or gearbox is used to drive the rotor, which rotates at a fixed speed. This mechanism ensures that the material is transferred through the valve in a controlled manner. Depending on the application, variable speed drives may be used for more precise control.

End Plates:

End plates are mounted on either side of the valve housing and help support the rotor and seals. These plates provide a rigid structure for the valve and facilitate the sealing and operation of the rotor.

Reviews

There are no reviews yet.