Description

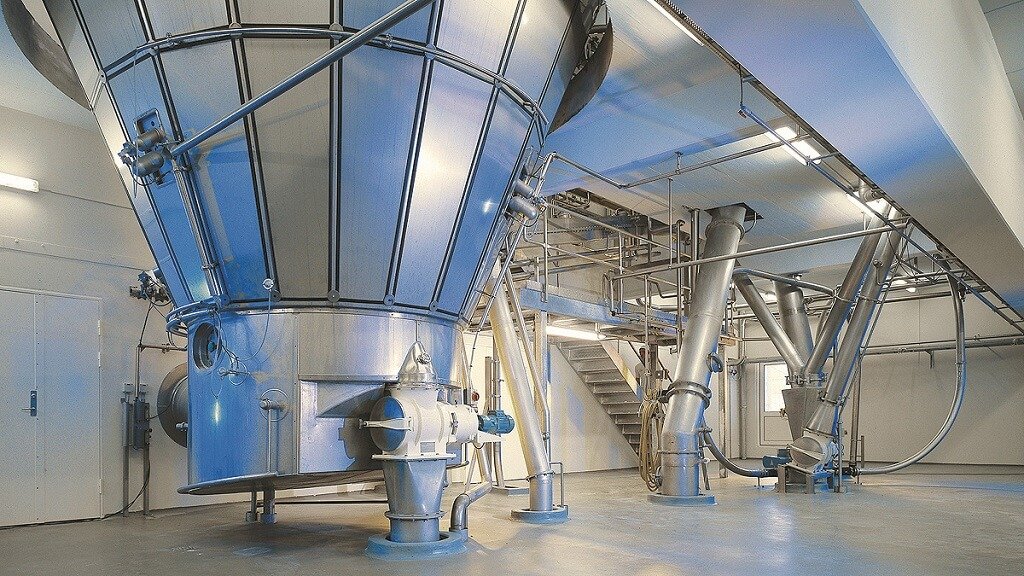

Atomizer Spray Dryer: Key to Efficient Drying and Powder Production

An atomizer spray dryer is an advanced equipment used for drying liquid feeds into fine powders or granules. The process works by atomizing (spraying) a liquid or slurry into a fine mist, which is then exposed to hot air to rapidly evaporate the moisture content, leaving behind a dry powder or solid. Atomizer spray dryers are commonly used in industries such as food processing, pharmaceuticals, chemicals, and ceramics, where consistent powder production with controlled particle size is crucial.

How an Atomizer Spray Dryer Works

The atomizer spray dryer operates based on the principle of atomization and drying. Here’s an overview of how it works:

Feed Preparation:

A liquid feed, such as a slurry, solution, or suspension, is prepared. The feed may contain the ingredients or active components that need to be dried, such as milk, juices, pharmaceuticals, or chemical solutions.

Atomization:

The liquid feed is then pumped into the atomizer at high pressure. The atomizer breaks the liquid feed into fine droplets using either centrifugal force or a high-pressure nozzle. This creates a fine mist or spray of droplets, increasing the surface area for efficient drying.

There are two main types of atomizers:

Rotary Atomizer: A high-speed spinning disk generates centrifugal force to break up the liquid into fine droplets.

Nozzle Atomizer: A high-pressure liquid is forced through a small nozzle to create fine droplets. This is more common in smaller-scale operations.

Hot Air Drying:

The atomized droplets are then introduced into a drying chamber, where hot air is blown in at high velocity. This air rapidly evaporates the moisture from the droplets. The temperature of the hot air is carefully controlled to prevent overheating or damaging the material being dried.

Particle Formation:

As the hot air contacts the fine droplets, the water content evaporates, causing the material to solidify into tiny powder particles. The particles continue to move through the drying chamber as they lose moisture.

Separation:

The now-dried powder particles are collected through a cyclone separator or a bag filter, which separates the fine powder from the exhaust air. The dried powder is then directed to a collection hopper or storage system.

Exhaust Air:

The remaining air, now containing the evaporated moisture, is typically expelled through the exhaust system. Some systems may also include air recycling mechanisms to improve energy efficiency.

Reviews

There are no reviews yet.